The benefits of Lean Warehouse Management:

- Deb Reardon

- Apr 26, 2023

- 1 min read

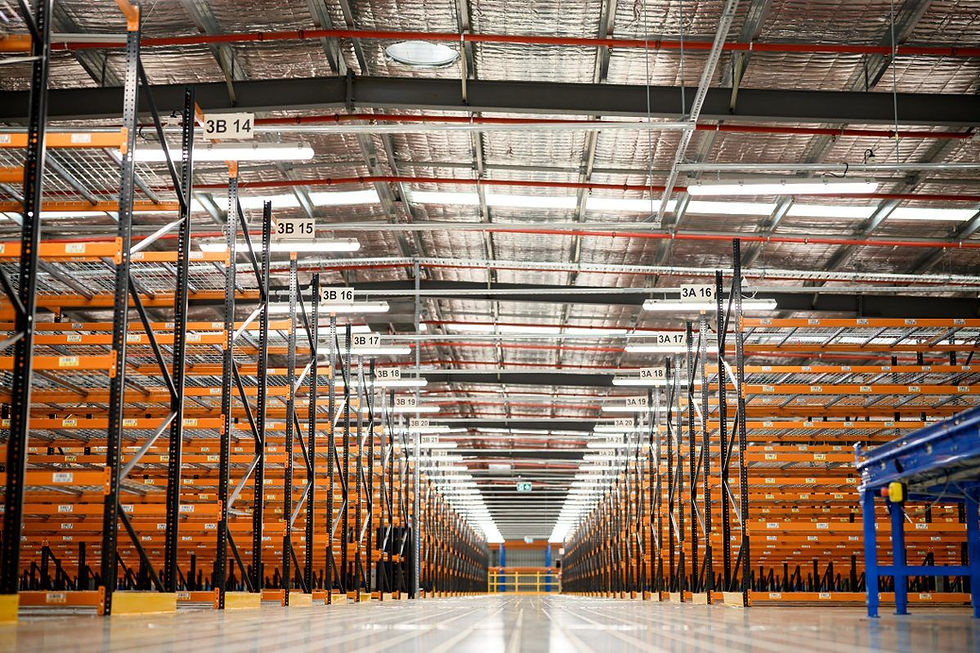

Lean Warehouse Management refers to a set of principles and practices aimed at improving the efficiency and productivity of warehouse operations. The benefits of implementing Lean Warehouse Management include:

Increased Efficiency: Lean Warehouse Management can help organizations optimize their warehouse processes, leading to reduced lead times, improved cycle times, and better utilization of resources. This can help organizations increase their operational efficiency and reduce costs.

Improved Quality: Lean Warehouse Management emphasizes the importance of continuous improvement, quality control, and waste reduction. This can help organizations improve the quality of their products and services, resulting in higher customer satisfaction and increased loyalty.

Better Inventory Management: Lean Warehouse Management can help organizations improve their inventory management by reducing excess inventory, minimizing stock-outs, and improving the accuracy of inventory tracking. This can help organizations reduce inventory holding costs and improve cash flow.

Improved Safety: Lean Warehouse Management emphasizes the importance of safety and can help organizations identify and eliminate safety hazards in the warehouse. This can help organizations reduce accidents and injuries, resulting in a safer work environment for employees.

Increased Agility: Lean Warehouse Management can help organizations become more agile and responsive to changes in customer demand and market conditions. By optimizing warehouse processes and improving inventory management, organizations can quickly adjust their operations to meet changing customer needs.

Overall, Lean Warehouse Management can help organizations improve their operational efficiency, reduce costs, improve quality, and enhance customer satisfaction, resulting in a more competitive and successful business.

Comments